Energy sector

Solving’s handling equipment is designed to suit a wide range of handling requirements in the energy sector.

For nearly 50 years, customers have relied on our solutions to address their specific handling needs.

Our offerings for this sector include Air Film Movers, wheeled Movers, and

Automated Guided Vehicles (AGVs), all tailored to their intended applications.

In the transformer and wind energy industries, Air Film Movers are predominantly used, although

customized wheeled forklifts are also installed in certain cases. For the nuclear and hydrogen industries, we conduct feasibility studies and provide AGVs to ensure efficient and safe handling processes.

In the oil and offshore industries, Solving trolleys are primarily supplied for use on oil platforms, while

Air Film Movers are utilized for managing large and heavy components at onshore production facilities.

Select industry sector to read more:

Transformers

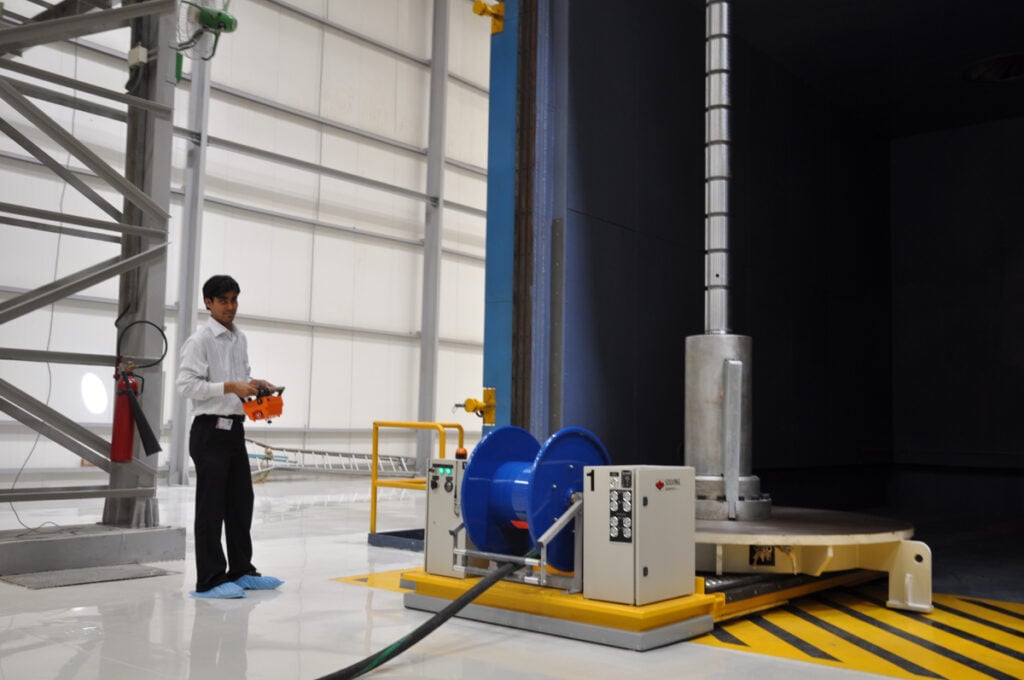

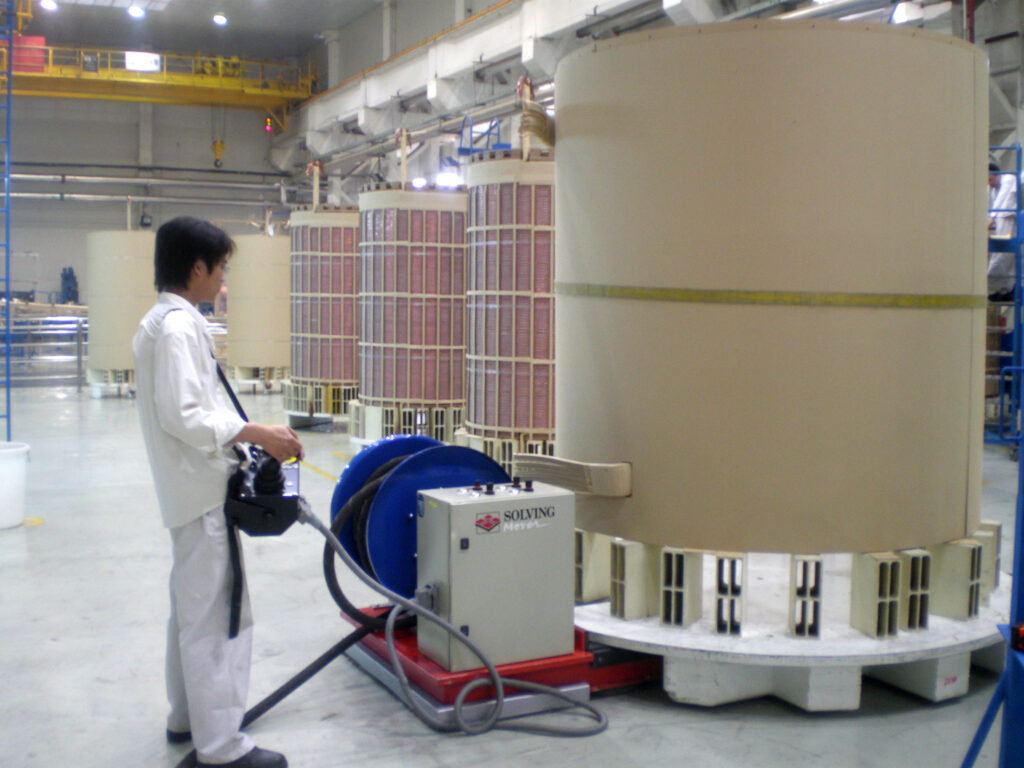

Solving provides a variety of transporters for handling transformers, windings, cores, and other

parts. Air film technology is particularly well-suited for moving transformers weighing several hundred

tonnes efficiently and smoothly through production areas, test facilities, and into vacuum ovens. Air Film

Movers provide the necessary freedom and flexibility to transport complete transformers

weighing 500 tonnes or more. With electric drives and integrated batteries, these Movers can operate independently of hoses and cables when unloaded, requiring connection only when moving a

loaded steel pallet.

In some cases, wheeled Movers are a more appropriate solution. For example, telescopic wheeled

Movers have been installed to ensure the smooth handling of transformer bushings, particularly in

factories with narrow layouts.

3 reasons why

1

State-of-the-Art control systems

Our latest control system technology enables optimal energy consumption, improving efficiency and performance.

2

High-capacity, compact Mover

The low lifting height of the air bearings, combined with the compact design of the Air Film Mover, ensures that the overall height of the handling equipment remains very low.

3

No floor wear

Air bearings distribute the load over a large surface area, resulting in very low point loads.

There is no friction and, consequently, no floor wear, because the Movers float on a film of air.

Wind power

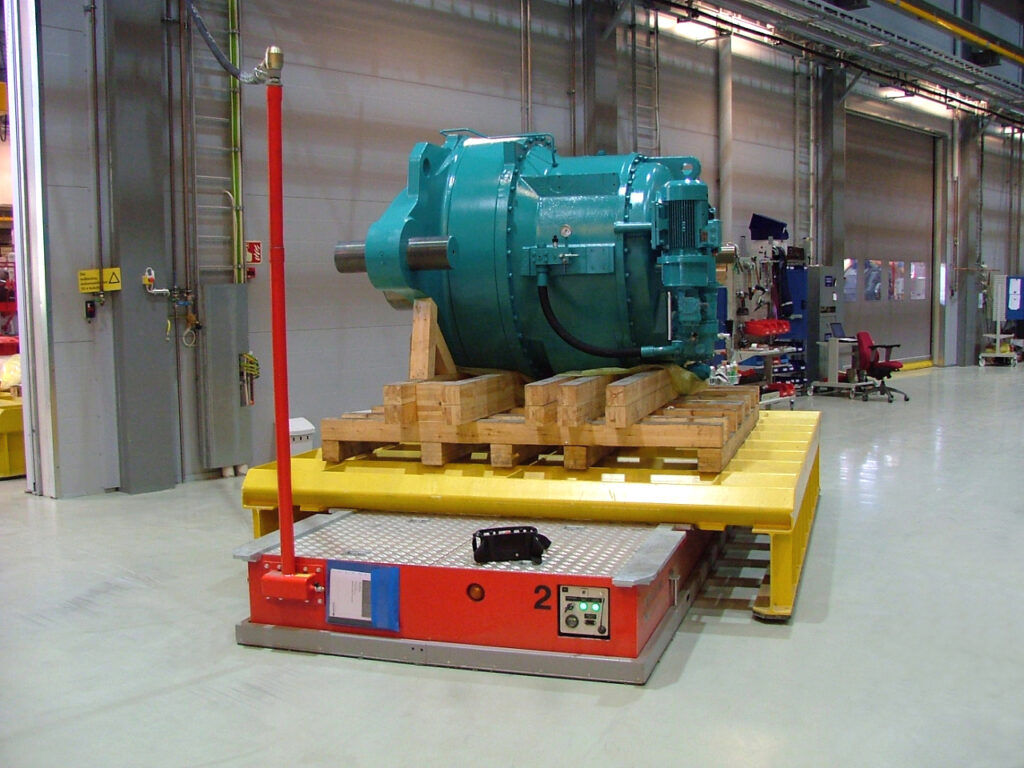

Solving provides a wide range of handling equipment for the wind power sector. Customized Solving Air Film Movers are used in the production of large and heavy wind turbines, while Automated Guided

Vehicles, AGVs, are implemented in assembly lines for wind power gearboxes and components.

We tailor our solutions to meet specific customer requirements, delivering efficient handling systems for heavy and bulky loads.

3 reasons why

1

State-of-the-Art control systems / Air Film Movers

Energy consumption can be optimized with our latest control system technology.

2

High capacity, compact Mover

The low lifting height of the air bearings in combination with a low-built Air Film Mover

means that the total height of the handling equipment is very low.

3

Customized handling equipment

The handling systems are customized to suit each customer’s requirements specifically

Book a consultation

Book a consultation with us today and we will contact you to set up the meeting.

Cables

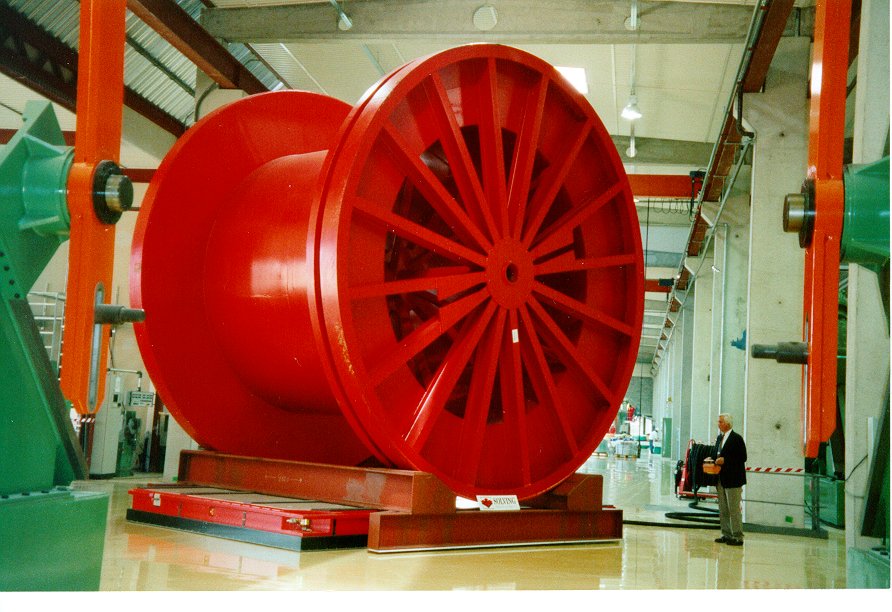

Various types of Solving Air Film Movers are installed to handle cables, cable drums or

umbilicals for heavy electrical and offshore applications. With capacities of up to 1000 tonnes or

more they allow both exact positioning and safe handling.

Nuclear

Electricity produced at nuclear power plants generates radioactive nuclear waste, and the waste

must be taken care of in a way that does not harm the environment. Solving AGVs are used in this

respect to transport disposal canisters safely in disposal facilities.

Read about Solving AGVs at Posiva’s ONKALO® Repository.

Oil /Offshore

We provide equipment for moving heavy machinery both offshore and onshore, i.e. on oil and gas

platforms as well as in facilities on land.

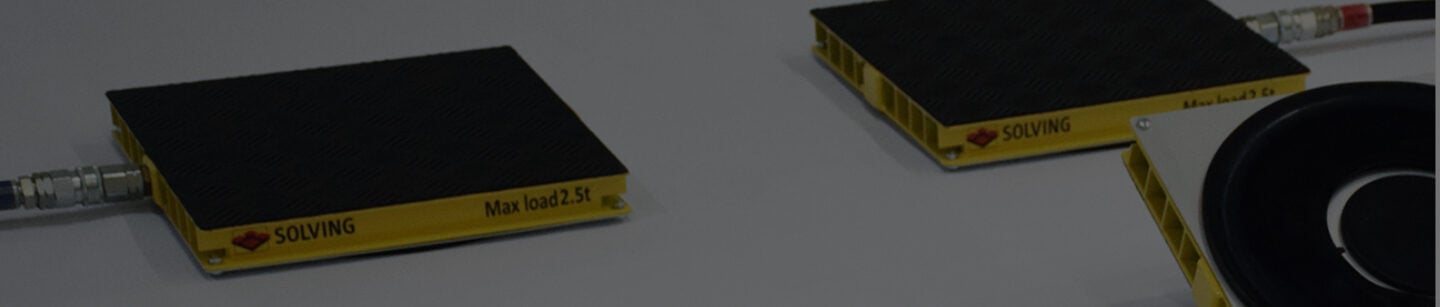

Solving air film Movers and modular air bearing systems (MLS) are used for flexible handling of

modules, cables, subsea pumps, and other heavy and bulky loads – either onboard oil platforms and

gas rigs or in production facilities on land.

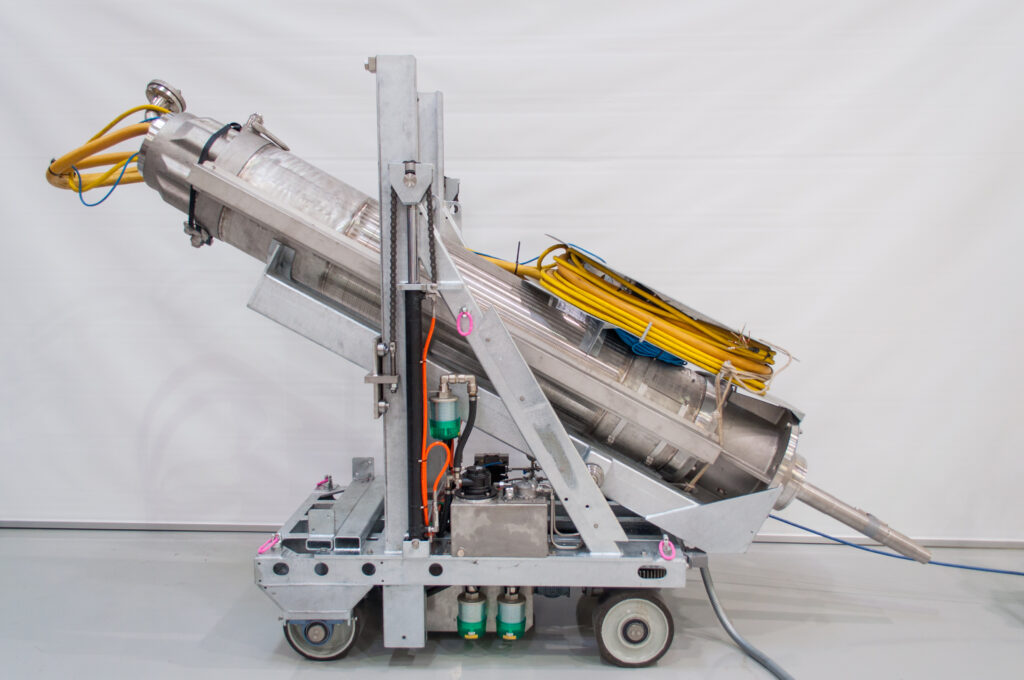

Solving pneumatic trolleys are used mainly for exchanging large and heavy components during

maintenance on oil and gas platforms. They are specifically designed and approved for EX

environments according to ATEX in zones 1 and 2, and if required certified to meet

the safety requirements set by the offshore industry.

Solving battery-powered trolleys are certified for ATEX in zone II for category 3G, IIBT3.

Hydrogen sector

Within the hydrogen sector separation and purification equipment are produced for the process and

emerging fuels sectors supporting global decarbonization goals. Solving automated guided vehicles

(AGVs) are installed to handle such separators along an assembly line.

Book a consultation

Book a consultation with us today and we will contact you to set up the meeting.

Cases

Get inspired by the cases below describing how our customers have benefited from our customized AGV systems, Air Film Movers, or wheeled Movers.

Contact us

Get in contact with us. We would like to hear from you.

Fill in the form or contact us directly.