Air Bearing Modules

Solving Air Bearing Modules (also called air skates, air casters or air skids) are designed to handle a variety of heavy loads and machinery. Air Bearing Modules are mainly chosen for less-frequent movement activities, whilst Solving Air Film Movers are installed for regular handling of heavy loads.

Do you need to move large machinery?

Solving Air Bearing Modules

- are easy to use

- can move loads of up to 360 tons

- are available in sets of 4 or 6

Fill in the form to request more information about buying a Solving Air Bearing Module set.

If you are in a situation where you need to get machinery or other heavy equipment moved temporarily you can rent our Air Bearing Module system. If you frequently need to get equipment moved, we recommend that you buy the system for in-house use.

Move heavy loads efficently on a cushion of compressed air

Solving standard Air Bearing Module Systems are perfect for handling almost any load from a few thousand kilograms up to 360 tons on a virtually friction-free film of air.

Typical applications where Air Bearing Modules are frequently used are: moving new machines into production facilities, taking out old machines from production areas, handling production equipment inside factories, moving ships around repair or production facilities, and container handling.

A Solving Air Bearing Module set is a cost-effective way of handling heavy and bulky loads; it is easy to set up and operate, and the same system can be used for moving various loads omnidirectionally, particularly advantageous when negotiating narrow areas. Air Bearing Modules are almost maintenance-free and do not cause any floor wear.

Do you recognize some of these challenges in your work?

- You need to move large machinery in your facilities every now and then

- Hiring external contractors becomes expensive

- The space where the load is to be moved is narrow

- Equipment used for moving heavy loads causes damage to the floor

If you replied yes to one or more of these, then our Modular Air Bearing Systems that come in different capacities can be an option for you.

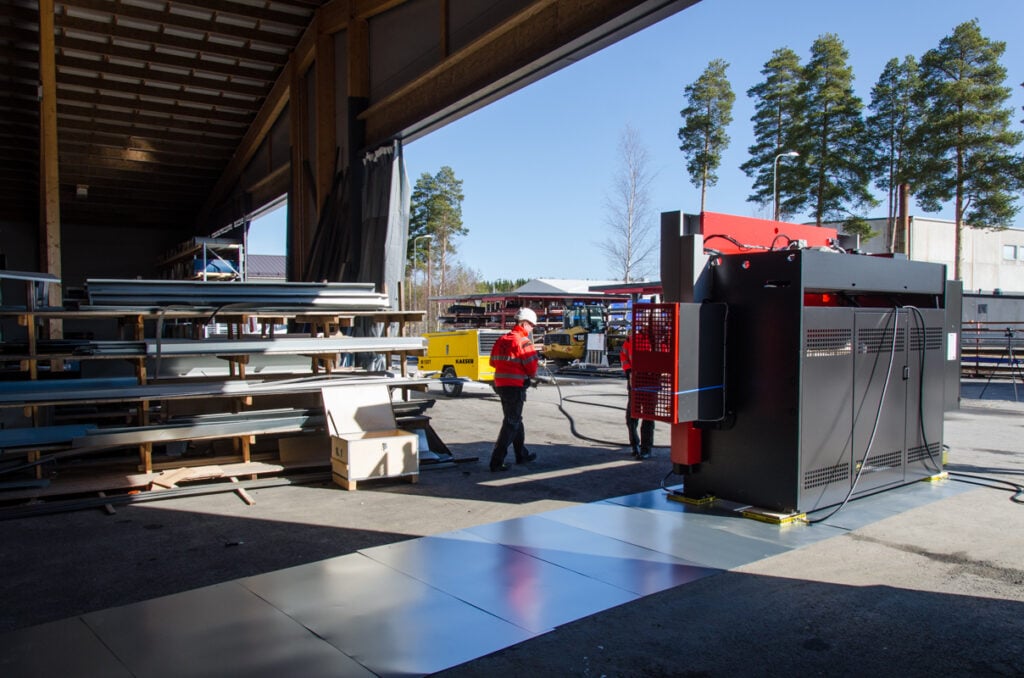

How an air bearing module system is used

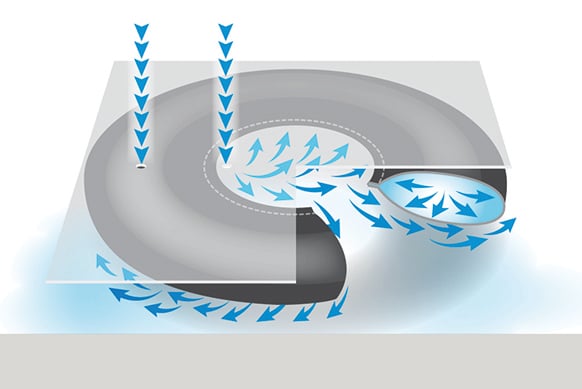

Generally, four or six air bearing modules are used to move large and heavy loads; to ensure maximum stability, at least three air bearing modules are required. They should be placed under the load, as far apart as possible, roughly dividing the weight of the load evenly between them. The modules are then connected to the control unit and the compressed air supply. Pressure regulators within the control unit are used to increase the air pressure in each module until the load is raised off the floor. A thin film of air is then formed under each module virtually eliminating friction and allowing a heavy load to be moved and positioned with ease and accuracy.

What does a set of air bearing modules (also called Air Skates, Air Casters or Air Skids) include?

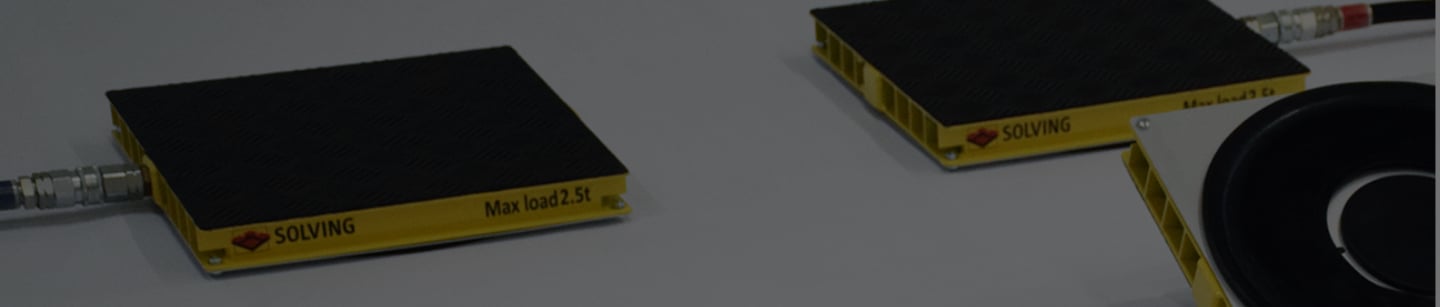

A set of Air Bearing Modules – the perfect solution for rigging and moving complex and extreme loads – includes:

- four or six Air Bearing Modules

- interconnection hoses with quick release couplings

- control unit with pressure regulator and gauge for each module, supply pressure gauge and plastic support bars

- supply hose including shut-off valve

- storage box, operating instructions

Examples of cases:

Air Bearing Modules were used for moving a 50-ton motor yacht into a yard’s production hall and out again after the refit. The controlled movement on air bearings gives confidence in handling also luxury yachts.

- Using air film technology was the only safe way to move the yacht because the clearance between the top of the yacht and the door opening was only a few centimeters.

A new 7-ton machine was brought into production facilities on air bearings.

- The machine was lifted by crane onto steel sheets and then moved on air bearings through the door opening.

- Steel sheets were used to cover cracks in the floor to ensure safe and good performance.

A new 8-ton machine was ‘floated’ on air bearings to it’s final position in a production hall. Thanks to the air bearings

- two 90 degree turns along the transport route could easily be passed.

- the machine could be positioned smoothly and precisely.

Do you want to start using our products?

Request a quote or more information.

Operational Requirements for Air Bearing Modules

Air supply

Air Bearing Modules use compressed air to move heavy machinery or other heavy loads and either normal shop air or a mobile compressor can be used.

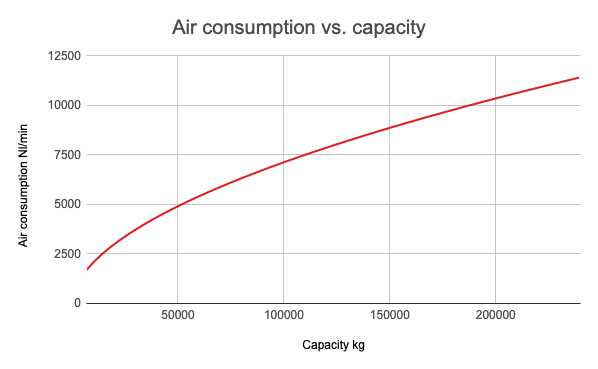

The air consumption is related to the weight of the load to be moved: higher weights increase air consumption. The chart below shows the general air consumption in relation to the weight of the load on an ideal floor surface. A substandard floor will increase air consumption.

Floor requirements

The quality of the floor surface affects the air consumption and the force required to move the load. A papersmooth level floor surface free of steps and cracks ensures ideal performance. For occasional moves substandard floors can be improved using thin sheet steel or PVC.

Read more about floor requirements for air film load handling in our whitepaper.

How to move the load

As the load floats on air, very little force is needed to move it. The general rule is that loads under 10 tons can be moved by hand on a good floor. For loads heavier than 10 tons, a towing device such as a forklift or winch is recommended for safe control. It should be noted that local conditions must always be considered, and operating instructions must also be followed to ensure safety.

Download our brochure

For more information download the brochure below:

FAQ

What is the difference between air bearing modules, air skids, air cushions and air casters?

These are all different names for the same product, i.e. a flexible bellow which is filled with compressed air and inflatedto lift off the floor and create a thin film of air, allowing the load it is carrying to float virtually friction-free. Read more about how the air bearing works here.

What kind of maintenance do air bearings require?

Air bearings require very little maintenance other than occasional cleaning of the surface to maintain efficiency.

What kind of floor is suited for air bearings?

The floor is an essential component of air film technology and certain floor qualities must be applied to ensure efficient operation. The ideal concrete floor is power-trowelled to achieve a flat papersmooth finish. Download our whitepaper to learn all about floor requirements.

What is the difference between air bearing modules and air skates?

Air bearing modules and air skates are different names for the same product, i.e. a handling system on air bearings designed for occasional moves, such as items of machinery. The set consists of air bearing modules, interconnection hoses, a control unit, a supply hose and operating instructions.

All you need to know about air casters

Air caster, air bearing or air cushion are all different names for the key component in pneumatic devices using compressed air to form a thin air film, on which heavy loads can be floated.

Contact us

Get in contact with us. We would like to hear from you.

Fill in the form or contact us directly.