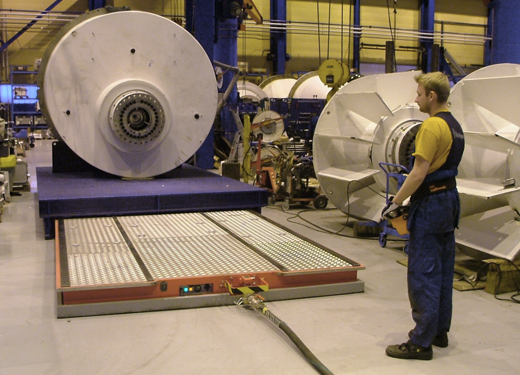

40T Floating propellers

Objective

The investment aimed at simplified production and easier handling between different production facilities. Rolls- Royce chose therefore a Solving air film Mover for the movement of azimuth thrusters from the assembly area to the final assembly area and then to a test zone in a different production facility.

Equipment

The thrusters are positioned on a load pallet during assembly and radio-controlled guidance gives the operator full control of the Solving Mover to enter the loaded pallet and pick it up in preparation for a move. In addition, the Mover has a large load capacity and a possibility of omni-directional driving.

Result

No cranes or other fixed installations are required for handling the thrusters. Another advantage of the Mover is the possibility of omnidirectional steering providing flexible manoeuvring in narrow production areas. Solving Movers are almost silent and easy to control. In addition, they provide safe material handling and a clean and pleasant production environment.