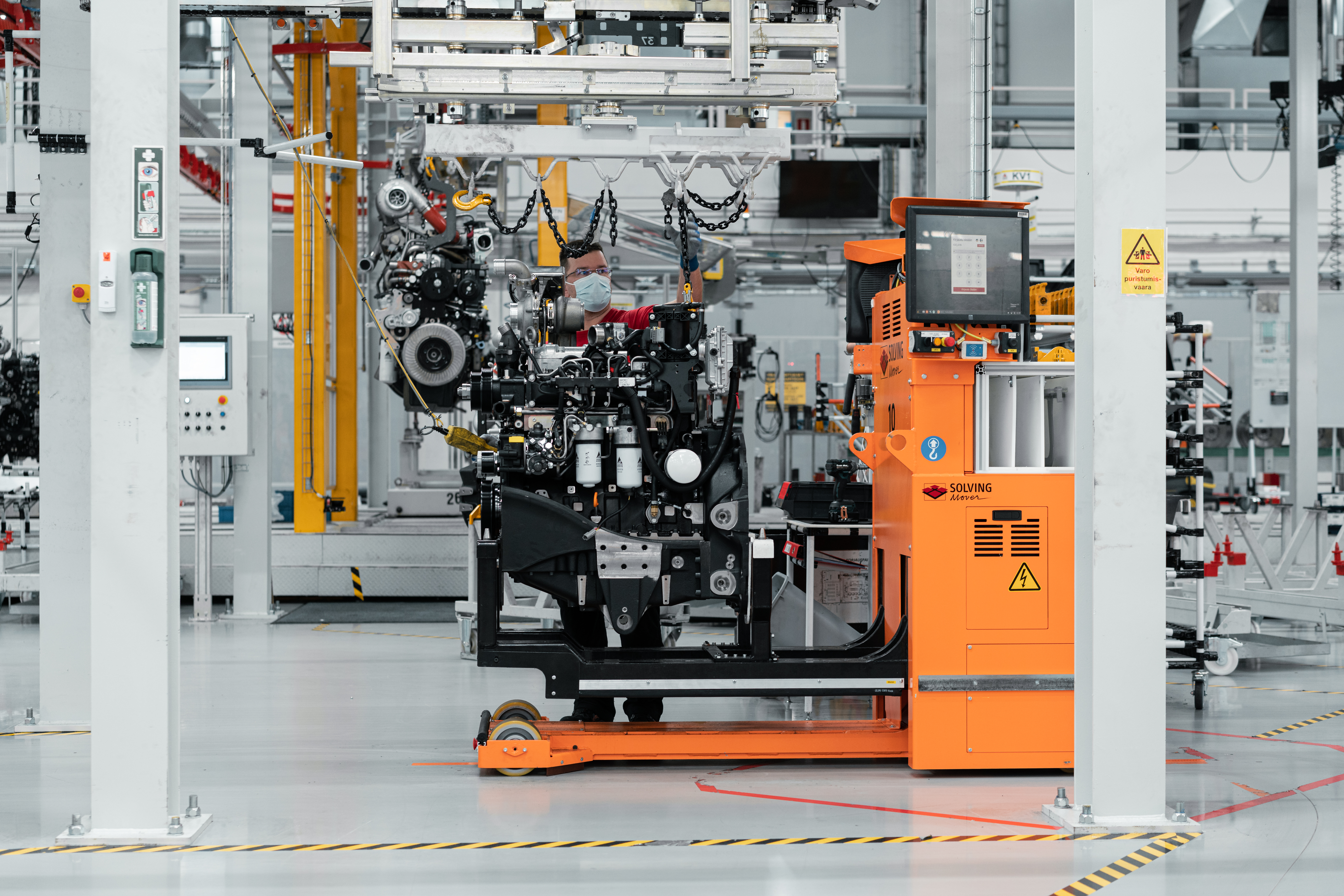

1,2-1,5 T Automated production line for engines

Challenge

The manufacturing process at an engine manufacturer needed to be modernized and streamlined.

Solution

Solving installed two AGV systems in the new assembly line along which 150 various engines flow every day. One system is continuously moving while the other one is a stop-and-go system. The AGV systems contribute to good ergonomics for the assemblers, and at the same time, the floors can be kept clear for personnel and material flow. They also provide flexibility ensuring that the processes can be adapted to changing requirements. With the AGVs system modifications can now be made even over a weekend, while it could take a couple of months with a fixed system.