1,2T (1,5T) Automated assembly and test

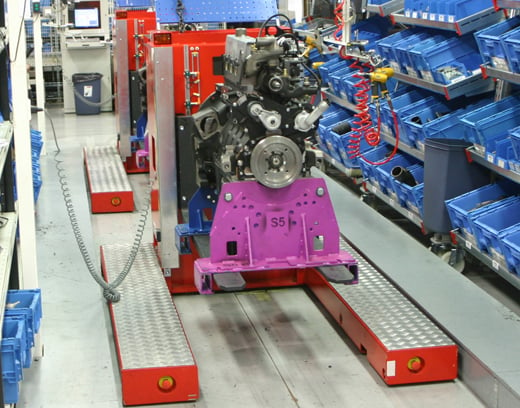

AGV for assembly

The AGV system for final assembly consists of ten automated vehicles using inductive navigation. Placed on assembly and transport jigs, diesel engines weighing up to 1200 kg are moved step by step through assembly using fork-lift Solving AGV Movers. The AGVs communicate with a PLC-based control system via radio and the indexing takes place by commands given by the operators.

AGV for test run

The AGV system for the test run facility consists of two automated fork-shaped Solving Movers with laser navigation used for stacking completed engines weighing up to 1500kg at a height up to 2,4 meters. Manoeuvering of the AGVs is integrated within the data system that follows the stream of manufactured engines through the intermediate storage and test run. The wagons are fitted with collecting vessels for liquids from the engines. The vessels are automatically discharged.

Result

Solving’s complete custom-made system suited the customer best considering the special requirements that handling of diesel engines set. Installation and start-up of the systems took place according to the agreed schedule. The automated assembly wagons also contribute to improved ergonomics and logistics at the final assembly stages. Despite all the programming required this automated system is very flexible for future changes in the layout compared to any competing technology.