Air casters

Air caster, air bearing or air cushion are all different names for the key component in pneumatic devices using compressed air to form a thin air film, on which heavy loads can be floated.

Air film technology was invented by a Finn

Way back to the 1930s a Finnish engineer, Toivo Kaario, invented the first craft to float on a small air caster above land and water. In the 1950s air film technology was developed for hovercraft in England and in the 1960s for internal moves in industries in the US. Nowadays air film technology is used in most imaginable industries.

Air casters are suited for heavy loads

Systems built on air casters are perfectly suited for moving very heavy loads, i.e. loads ranging from a few hundred kilograms up to a thousand tons or more. Air caster handling systems are best suited for indoor movement and rather short distances. Air casters are equally applicable for simple manually operated units as for complex automated handling systems. Learn more about Solving air film Movers here.

Air caster – a key component of a superior load handling method

In many respects air film technology is superior to any other conventional handling method. When compressed air is forced out through the air caster, a thin film of air is formed between the air caster and floor. In this way, friction is reduced to a minimum, thus allowing heavy loads to be moved with very little effort. For instance, only 1 kg power is required to move a load weighing 1000 kg.

The weight of the load is divided over a large area, thus there is no point load and floor wear or damage can be eliminated. Air casters allow omnidirectional movement, meaning that air caster systems are very flexible and large, heavy and bulky loads can be moved and positioned with ease in any horizontal direction.

Certain requirements must be fulfilled

To work properly air casters require a paper-smooth floor without inclinations. Normally a standard concrete floor is good enough. Also compressed air needs to be supplied to the air casters; therefore they must always be connected to air supply when the load is being moved. Standard shop air can be used.

How does the air bearing (air caster) work?

When the air bearings are supplied with compressed air, the following sequence of events takes place:

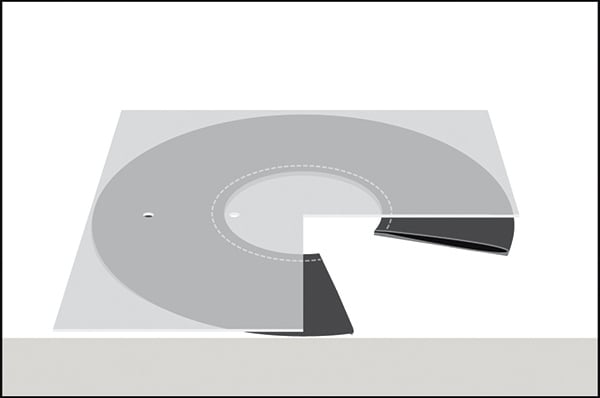

- An air bearing in its flat state before air is connected.

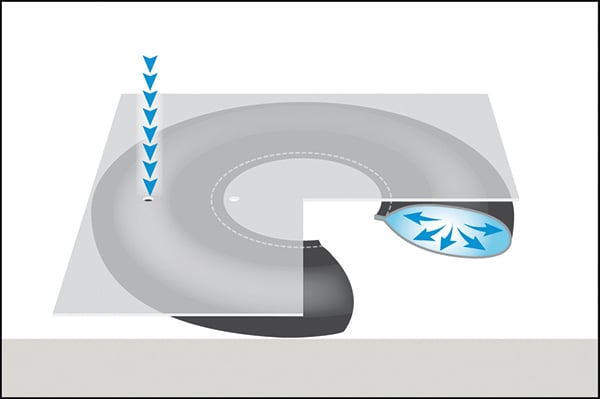

- When air is connected, the air bearing inflates and the load is lifted off the floor.

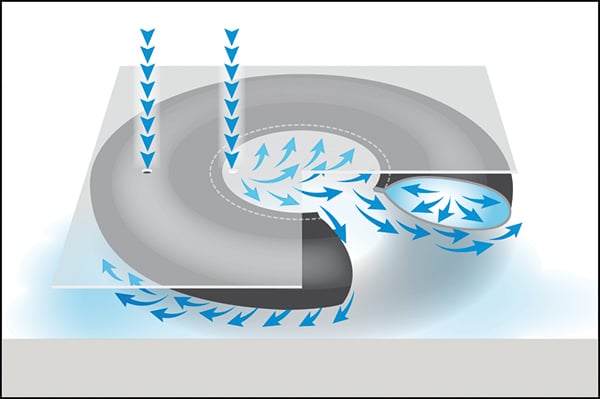

- When the pressure in the air bearing is higher than the counterpressure of the load, air flows between the air bearing and floor, and a thin film of air is formed on which the load floats virtually without friction.

View an animation showing how air bearings or air casters work and how they can be used in transporting heavy loads in industrial environments:

Click here to view the video with air caster transporters on youtube.